3 Ways DriveWorks Software Helps Automate the Quoting Process

A few months ago, a friend of mine in plastics manufacturing shared that his firm was experiencing a substantial uptick in production. He went on to mention that to handle the surge in productivity, his company was investing into a custom tool that would automate portions of the production process.

Earlier in the year, I also remember a former colleague (who now owns a construction equipment resale business) saying that after several years of slumped sales, business was finally picking up. He said that prior to this year, corporations simply were not making long-term investments in equipment — but that all seemed to be turning around for 2017.

These personal observations had us wondering: are these scenarios a coincidence? Or indicative of a larger trend? Generating quotations is a key piece of your business; quotes serve as a critical communication vehicle that connect your prospective customers to your product. And that means creating those quotes efficiently and effectively is important to your sales team, design engineers and other key staff. This is especially true for companies that create custom solutions and must provide special diagrams and other features with their proposal.

After the popularity of our recent blog post, Design Automation Software: What It Does And Why It’s a Game Changer for Manufacturers, I thought it was time to take a deeper dive and discuss some specific ways that DriveWorks software can help automate the customer-quoting process. So I rounded up ideas from our design engineering team – and here’s a look at the three features that have made the biggest impact.

1. Data Acquisition Using Group Tables

Every time a customer quote is generated for a custom tool (in Steiner’s case, The Autofacer), DriveWorks will collect all pertinent information into a table. That aggregated data can be exported from DriveWorks into Microsoft Excel and customized based on certain criteria (for example, by tool or by distributor).

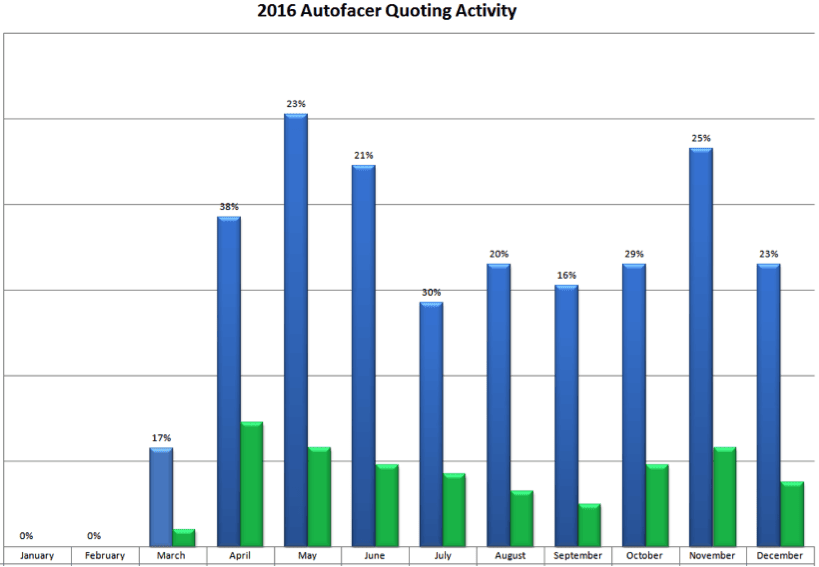

These group tables/charts, which can then be manipulated according to the specific criteria you’d like to see, essentially works like a live database in Excel. They are updated whenever the data in the Excel table is updated from DriveWorks, providing real-time visibility into customer order tracking. For example, how many open orders do we have? Which type of tools are being ordered? What sizes? How many quotes went on to become orders? All of this information can be extremely useful for the sales and management team.

Diagram 1. This chart (which is updated whenever the data in the Excel table is updated from Driveworks) shows month-by-month quoting activity for The Autofacer. The blue columns show the number of quotes and the green columns show the quotes that became orders.

2. Built-In Macro Ability

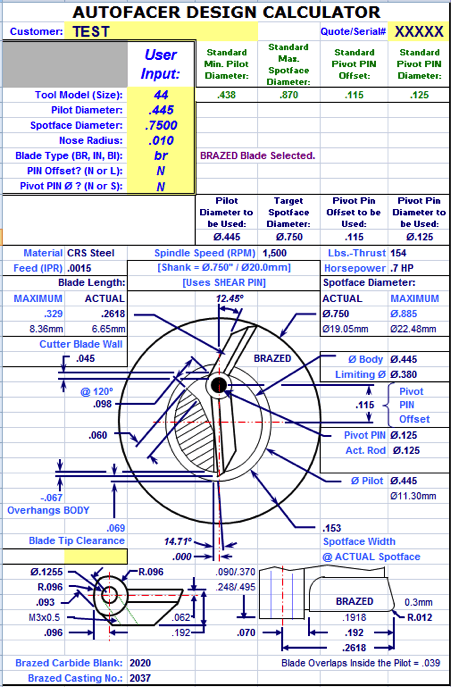

Let’s say your company is generating a quote for a custom tool or machine. Chances are, several calculations must be performed in order to determine the exact specifications of that custom order. At Steiner, for example, we perform several calculations using a secondary source, Microsoft Excel.

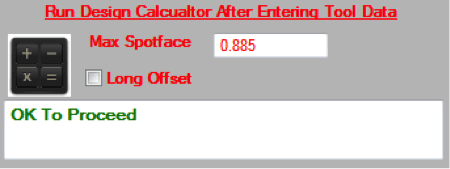

DriveWorks works in tandem with those secondary sources, with built-in macros that export data to perform key calculations (shown in Diagram 2a). Then the data is “returned” to the software to inform the criteria and next steps in the quote generator (such as tool size and prompts like the “OK to proceed,” shown below in Diagram 2b). These functions, which are performed behind the scenes, make for a smoother and more efficient process – and save users time from having to reference data from one source and reenter it in another.

Diagram 2a. DriveWorks exports data to a secondary source (Excel) where design feasibility for a tool application is calculated. It then “returns” that data to the software.

Diagram 2b. Data is imported from Excel back into DriveWorks to inform the next step. In this case, it has verified that the tool size selected meets customer requirements and the design team is “OK to proceed” with quoting.

3. Built-in Intelligence

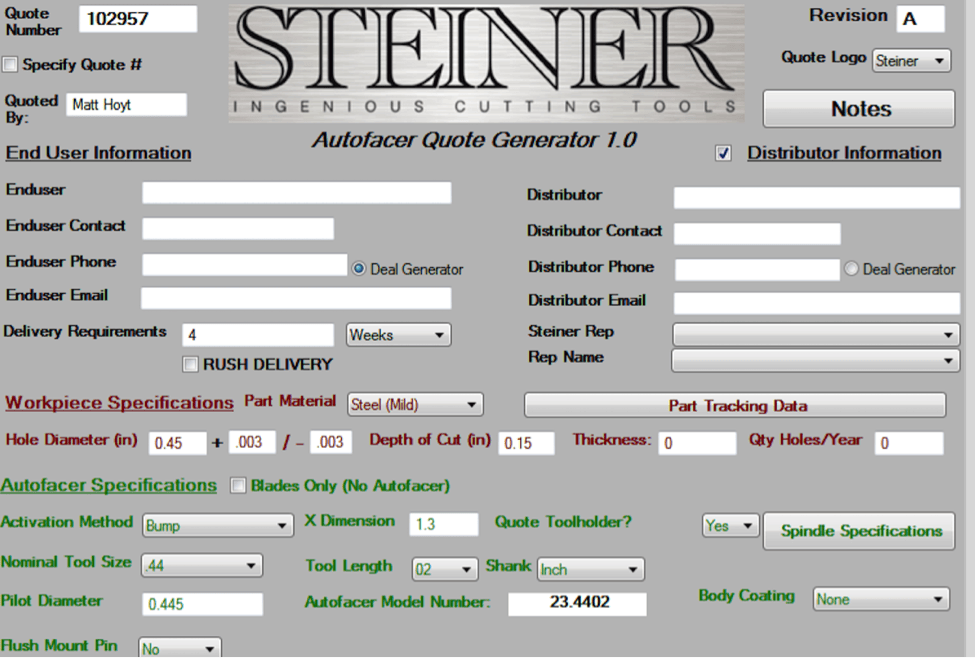

Our third favorite feature using DriveWorks for quoting is the fact that the software uses built-in intelligence to guide users through the quoting process. Here again, we’ll use the example of a quote request for the Autofacer.

DriveWorks helps pre-populate certain fields with the data it “knows,” thereby reducing the number of decisions that could otherwise vary throughout the quoting process. This type of intelligence creates time-saving efficiencies in quoting – and delivers more consistent end results, regardless of who is inputting the data.

Diagram 3. DriveWorks uses built-in intelligence by pre-selecting data (shown in red) based on certain criteria. This helps users make “smart” selections and yields more consistent quoting.

Every manufacturing business is unique, of course – but I hope you find these three tips helpful as you think about some ways to streamline your own customer quoting process. At Steiner, we’re always looking for ways to improve productivity and create efficiencies, and we enjoy sharing them with our readers!

Sign up now (see form at top right) for Steiner updates. And as always, if you have questions don’t hesitate to contact me