Autofacer

The World Leader in Automatic Back Counterboring Tools

AUTOFACER

The World Leader in Automatic Back Counterboring Tools

Features of the Autofacer

What sets the Autofacer apart from other back spot-facing tools?

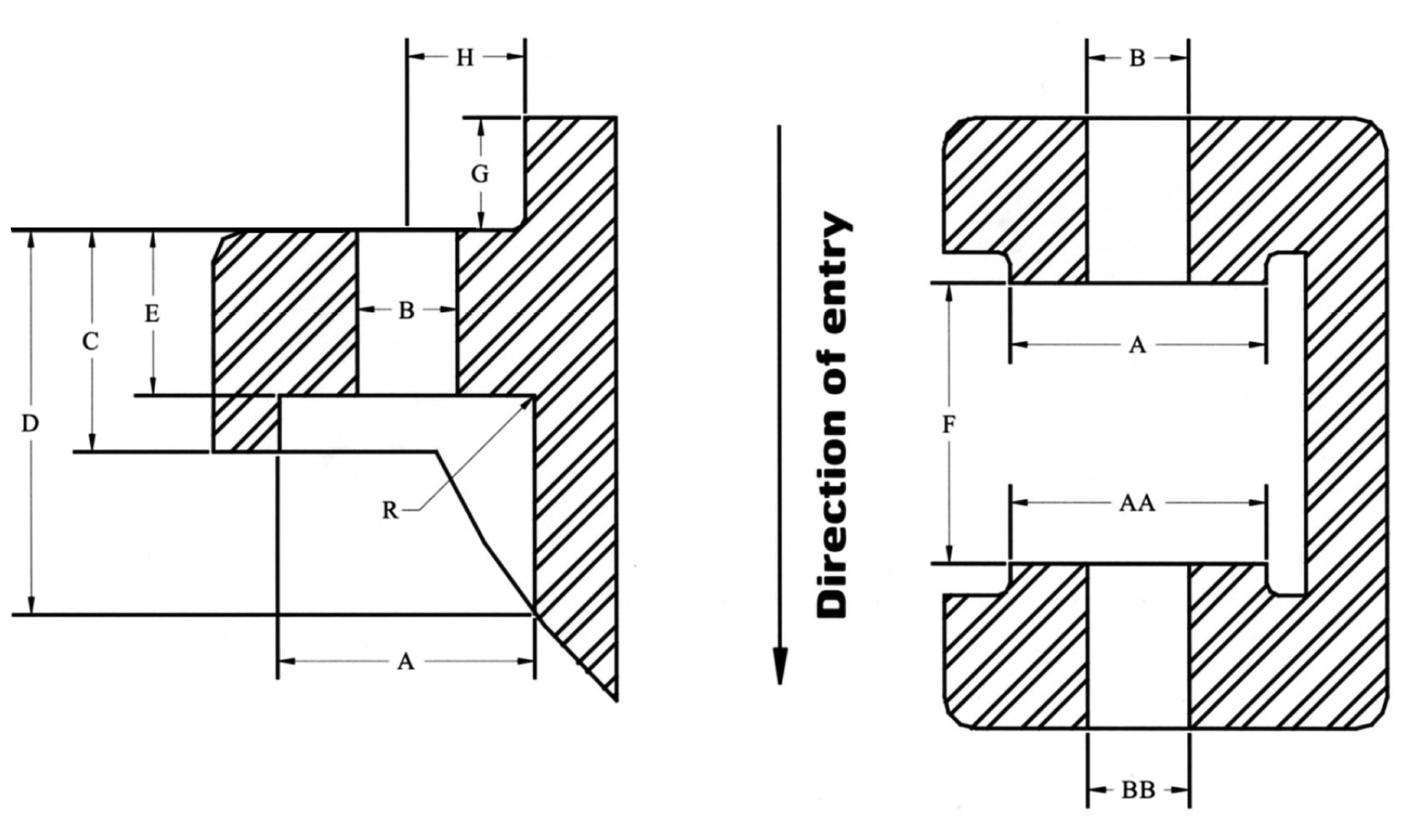

The Autofacer is an ingenious automatic back counterboring tool that allows a machinist to reach through a hole and machine a circular feature* on the back side of the part automatically. This is accomplished by folding the cutting blade into the shaft of the tool body allowing the tool to pass into the part. Once the tool has entered the part, the cutting blade is mechanically opened and cutting may begin.

Steiner Technologies is the OEM of the Autofacer since 1968 and we continue to be the world leader in automatic back spotfacing and back counter boring tools.

* Circular features might include a spot face, counterbore, countersink, chamfer, spherical radius, or some combination thereof.

Activation Methods

How it Works

How it Works

- Cone grips the face of the workpiece to open and close the blade (must be a machined surface)

Advantages

- Reliable performance on any machine tool, CNC or manual

- Cost-effective alternative to high-production tooling

How it Works

How it Works

- Utilizes the inertia generated during rapid spindle acceleration to open and close the blade

Advantages

- Ideal for modern CNC machines with rapid acceleration and deceleration

- Cost-effective alternative to high-production tooling

- In-Stock & Ready to Ship

- Inch & Metric Weldon shanks available

- Fully supported in pilot hole during cutting

- Utilizes machine spindle inertia to open & close the cutting blade

- Shear pin design protects the tool investment, workpiece and machine spindle in the event of tool overload.

Counterbore Ø Range:

- 9.5mm (.375″) to 33mm (1.299″)

How it Works

- Utilizes an anti-rotation device during spindle reversal to open and close the blade

- A Torque Bar Driver or an Arrestor-rod is required

Advantages

- Perfect for high-production runs that require the maximum degree of reliability

- Ideal for transfer lines and CNC machines

How it Works

- A rack and pinion gear opens the blade like a jack knife

- Available in Torque Bar and Coolant activated configurations

Advantages

- Extended spotface-to-hole size ratio (largest in the industry)

- Perfect for internal machining in differential gear cases

How it Works

- High-pressure coolant drives the blade open

- Spring-pressure closes the blade when the coolant is shut off

Advantages

- Simple to set up and run

- Perfect for high-production runs

- Ideal for machines with high-pressure, filtered coolant systems

How it Works

- Pads grip the inside diameter of the pilot hole to open and close the blade

Advantages

- Ideal for hole sizes greater than 2.25 inches where front (& back) spotfacing is required

How it Works

- A tapered pilot locates on a process bore supporting the tool a full 360 degrees

- Adjustable insert cartridge

- Available in Torque Bar activated configurations

Advantages

- Excellent size control and repeatability

- Capable of holding high-precision tolerances of .0001″ (.0025mm)

- The Steiner KA Autofacer is a modular semi-standard front and back counterboring system that was designed for machining seat pockets and clearance bores in Gate Valves

- The KA Autofacer utilizes expandable bushings and modular dampeners to support the tool when cutting which eliminates the need to hold a tight diameter tolerance on your flow bore

- Our modular connection allows lengths to be built out in 6” and 12” increments.

- The KA Autofacer can be used on standard CNC machine tools- No “W” axis is required.

The 5-Step Steiner Process

Full Assessment:

All projects start with a thorough assessment of your needs. What problems are you facing – and how can we help solve them? Our application engineers can best determine these factors when you submit your online assessment form, which is typically followed up with a phone call.

No Obligation Quote:

Once the problem is identified and it is determined that Steiner offers a solution, we will generate a no-obligation quote and send it to you within 24 hours.

Design:

After Steiner receives an order, the tool is designed and approval drawings are sent to the customer. Our engineering team uses state-of-the art 3D modeling and design software to ensure consistency across all Steiner products and reduce the tool design lead time. Steiner will send the approval drawings and upon request, access to a 3D model file.

Production:

As soon as you approve and sign the design proposal, production begins. All tools are made in-house and our quality and operations team will closely monitor production every step of the way, including a stringent final inspection and assessment prior to shipment.

Delivery & Service:

After tool delivery, our dedicated team is on-call for assistance. Additionally, we have a national network of support and will enlist a local Steiner sales rep to help with your first tool runoff to guarantee success.

Video Demos

What do Steiner solutions look like in action? Access our video library for live demos.

What is the Autofacer?

See what sets it apart and take a look at its applications in actions.

Ingenious Innovations: Custom Cutter Blade Fixture

Watch as we unveil our custom machining fixture, optimizing the production of Cutter Blades and Master Holders for the Autofacer, Automatic Back Spotfacing Tool.

Torque Bar Autofacer with LED Indicator Ring

This video demonstrates the functionality of our new LED Indicator Ring system for our Autofacer automatic back counterboring tools.

Autofacer: Power generation component

By customer request, this Autofacer is hand-activated with extra-long length-to-back-spotface parts with different cross sections.

Autofacer: Bump style demo

The Autofacer is capable of performing heavy interrupted cuts and very large metal removal.

Autofacer: Torque Bar style

Watch a Torque Bar style Autofacer machine the seat pockets of a gate valve.

Autofacer: Windmill Component

Watch a live demo of the Autofacer machining a windmill component.

Autofacer: Heavy equipment part

Watch it perform back spotface on a steel heavy equipment part; cutting diameter of Ø10.50″.

Bump-Style Activation Method

See how the Bump-Style or Cone Activated Autofacer Functions

Torque Bar Activation Method

See how the Torque Bar Activated Autofacer Functions

Flywheel Activation Method

See how the Inertia or Flywheel Activated Autofacer Functions

What is the Autofacer?

See what sets it apart and take a look at its applications in actions.

Ingenious Innovations: Custom Cutter Blade Fixture

Watch as we unveil our custom machining fixture, optimizing the production of Cutter Blades and Master Holders for the Autofacer, Automatic Back Spotfacing Tool.

Torque Bar Autofacer with LED Indicator Ring

This video demonstrates the functionality of our new LED Indicator Ring system for our Autofacer automatic back counterboring tools.

Autofacer: Power generation component

By customer request, this Autofacer is hand-activated with extra-long length-to-back-spotface parts with different cross sections.

Autofacer: Bump style demo

The Autofacer is capable of performing heavy interrupted cuts and very large metal removal.

Autofacer: Torque Bar style

Watch a Torque Bar style Autofacer machine the seat pockets of a gate valve.

Bump-Style Activation Method

See how the Bump-Style or Cone Activated Autofacer Functions

Torque Bar Activation Method

See how the Torque Bar Activated Autofacer Functions

Inertia Style Activation Method

See how the Inertia or Flywheel Activated Autofacer Functions

Autofacer: Windmill Component

Watch a live demo of the Autofacer machining a windmill component.

Autofacer: Heavy equipment part

Watch it perform back spotface on a steel heavy equipment part; cutting diameter of Ø10.50″.

Case Studies

It’s not enough to simply say that Steiner increases part profitability by: reducing part process time by 80%+, eliminating costly secondary operations and automating your processes. Take a look at these real stories of customer outcomes:

Request A Quote for an Autofacer

Do you have an application that an Autofacer could improve? Fill out the short questionnaire below and we'll contact you!